Printed Circuit Board Assemblies (PCBAs) at YXD

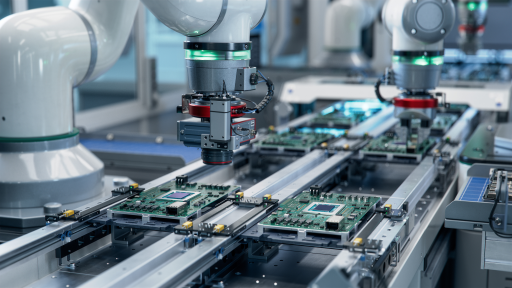

At YXD, we provide a full spectrum of PCB assembly services tailored to meet the unique requirements of each client. Whether you are looking for initial prototypes or large-scale production runs, we leverage cutting-edge technologies and maintain rigorous quality control processes to deliver PCBA solutions that ensure optimal performance, reliability, and efficiency.

Surface Mount Technology (SMT) Assembly

Our SMT assembly process is designed for efficiency and precision, enabling us to handle even the complex boards with fine-pitch components. By utilizing advanced placement machines and state-of-the-art soldering techniques, we strive to ensure that each component is accurately placed and reliably connected. This results in high-quality PCBAs that perform seamlessly, meeting the specific needs of your project.

Key Benefits:

-

High-speed, automated assembly

-

Precision placement of small and fine-pitch components

-

Reliable electrical connections for complex designs

Through-Hole Assembly

For applications that demand mechanical strength and long-term durability, through-hole assembly is the preferred choice. Through-hole technology provides strong mechanical bonds, making it ideal for components that will experience high stresses or environmental challenges. Our technicians take great care in ensuring each connection is robustly soldered, resulting in highly reliable PCBAs.

Key Benefits:

-

Strong mechanical bonds for high-reliability applications

-

Ideal for components with high current or large sizes

-

Suitable for harsh environments, such as industrial and automotive electronics

Mixed Technology Assembly

For boards that require a combination of surface-mount and through-hole components, we offer Mixed Technology Assembly. This process blends the benefits of SMT and THT to provide a flexible and efficient solution for complex designs. Whether it's single-sided or double-sided assemblies, we ensure that each component is securely placed and optimally connected for long-lasting performance.

Key Benefits:

-

Flexibility in handling both SMT and THT components

-

Optimal performance for multi-component assemblies

-

Suitable for high-density and complex PCBs

Why Choose YXD for Your PCBAs?

1. Cutting-Edge Technology

At YXD, we employ the latest technologies in PCB assembly to deliver highly accurate, reliable, and efficient results. Our modern equipment and techniques enable us to tackle even the most challenging projects with precision.

2. Rigorous Quality Assurance

We are committed to delivering PCBAs that meet the highest quality standards. Every assembly undergoes comprehensive testing, including AOI inspection, functional testing, and X-ray analysis to ensure it meets your specifications and exceeds industry standards.

Testing Capabilities Include:

-

In-circuit Testing (ICT)

-

Automated Optical Inspection (AOI)

-

Functional Testing

-

X-ray Inspection

3. Expert Technicians

Our skilled and experienced team of technicians brings decades of expertise to each project, ensuring that your PCBAs are assembled with precision and care. We take pride in the craftsmanship of every board we produce, ensuring that every assembly meets the exacting standards of our clients.

4. Scalable Solutions for Every Project

Whether you're building a few prototypes or require high-volume production, our PCB assembly processes are flexible and scalable to accommodate projects of all sizes. We work closely with you to ensure that your project stays on schedule and within budget.

Volume Flexibility:

-

Small-volume prototypes

-

Medium-volume production

-

Large-scale manufacturing